Interactive flat panel displays (IFPDs) with infrared touch screens are gaining popularity in recent years.

Compared with smart projector boards, which were widely applied to education, IFPDs is more convenient and practical.

You do not need to calibrate the image projector before lecturing; with LED lighting technology, IFPDs provide a clear image all the way; and thanks to the IR touchscreen, you can annotate your presentation with almost anything, a dry/wet finger, pen, or stylus.

However, let’s focus on the IR touchscreen today to see how it is properly utilized to improve the user experience.

What Is An Infrared Touchscreen?

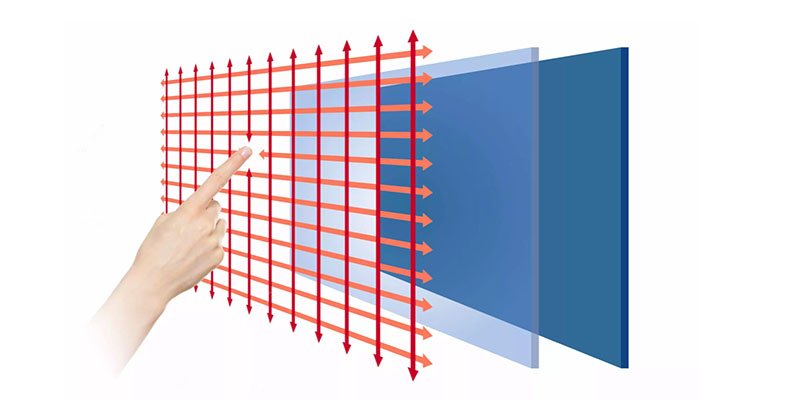

An infrared touch screen consists of an LCD monitor, IR touch frame, and infrared touch overlay.

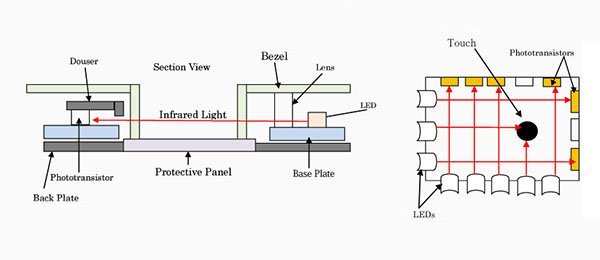

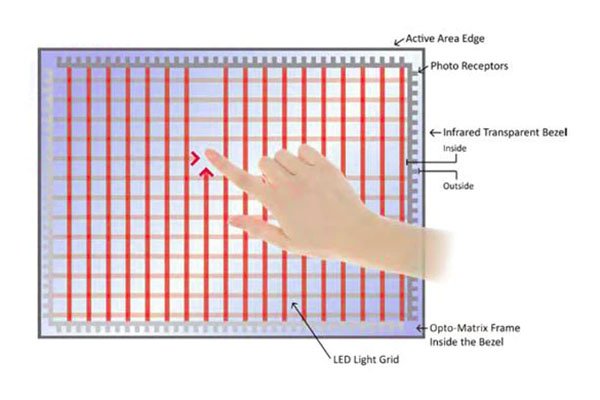

Commonly, the overlay is a piece of protective glass hemmed in by the IR touch frame, in which Infrared LEDs and photodetectors are embedded. A kind of optical bezel will be inserted between the glass and the frame to fix the frame and transmit infrared light emitted by those LEDs.

Through the optical bezel, IR LEDs emit invisible infrared beams forming grids on the surface of the overlay, Photodetectors are installed across from the LEDs to detect interruptions of beams if touch events on the overlay happen.

How Does Infrared Touchscreen Work?

The infrared touchscreen works by detecting interruptions of infrared beams emitted by LEDs embedded in the frame around the touchscreen overlay.

There are two rows of IR LEDs, which generate horizontal and vertical invisible IR beams. They form a large beam grid that covers the surface of the overlay. In the meantime, two rows of photoreceptors are installed on the opposite side of the LEDs.

As long as an opaque object touches the surface, it will blot out the light beams. Photoreceptors in both directions (vertical and horizontal) can detect this interruption by that object, finally localize the x and y coordinates, and then send the signal to the processor to respond with relevant action.

To know more details of its structure and workings, you’d better walk into a workshop to learn its assemble process. Most of the time, we do not have that chance, however, regular maintenance work offers you the opportunity to check its components inside.

Let’s review the video below.

How To Install An Infrared Touch Screen Interface (Overlay)?

Maintenance is a good solution to sustain the equipment with an IR touchscreen, however, it entails cleaning and installing the interface (overlay).

- First, you need to remove screws from the bracket, which is used to fix the LCD monitor and touchscreen overlay.

- Second, remove the bracket

- Third, put the overlay on a flat workbench.

- Clean the dust inside the sheet metal frame with a canned air duster

- Clean the inside surface of the glass overlay, by using mild cleaner only, do not use chemical solvents

- Clean the surface of the monitor

- with the help of a partner, gently install the overlay back

- return the bottom bracket to its original position

- secure the bracket with new screws

Alternatively, Let’s go through this video to learn more

Benefits Of Infrared Touch Screen Technology

Besides IR touch, resistive touch and capacitive touch in today’s market are also mature technology, which performs stably.

Resistive or capacitive touch screen technology exists even longer than IR touch screens.

But, why do engineers choose infrared touch screens for interactive whiteboards, which are widely used for business meetings and distance learning.

- Economical option – compared to other touch screens, the cost of IR touch screens is relatively cheap in large size.

- Better display – without other substance between the LCD and overlay, IR touch screens offer the best light transmission, so they can render more vivid images without color and brightness loss.

- Supports multi-touch – with windows and android 9.0 double OS, it can support as many as 40 touchpoints simultaneously. That means it can support up to 4 students interacting together on an IFPD.

- Short response time – commonly less than 8ms, IR touch screens localized touch events by detecting light interruption, so they are accurate and quick to respond with actions.

- Better writing experience – its overlay is often a piece of tempered glass, it is smooth to write on it.

- Free of scratches – since the LCD monitor is protected by glass overlay, so you can rest assured that there will no scratches problems

- More flexible in customizing screen sizes – by adjusting the numbers of LEDs and photodetectors embedded in the overlay frame, you can fit any custom-made monitor with an infrared touch interface

- Maintenance – there is no adhesive substance between the monitor and overlay, so you can disassemble the two parts freely by releasing a few screws when doing regular maintenance, such as cleaning the surface, and wiping dust.

- Clear images – compared with many camera or projector-based systems, equipment with IR touch screens often adopts backlight LED. So, wherever lighting environment they perform in, they can provide clear images to the audience.

- 4K resolution – they can support 4K resolution screens and work well with high pixel monitors

- No loss of screen display – Since LEDs and sensors are designed to be fixed in the frame that is around the monitor, the screen can display an unrestricted view.

- Write with any object – you can write on an IR touch screen with anything, a bare finger, a gloved finger, wet hands, or a pen, as long as it is not transparent.

- No calibration – a traditional smart projector board may require regular calibration to display correct pictures, however, devices with IR touchscreen do not need to calibrate the IR LEDs and sensors to guarantee a normal function.

- No pressure is required to write – Resistive touch screen technology perceives the writing track by pressure, which can damage the screen after a long time of usage, while IR touch screen technology by detecting light interruption, so you can write freely without having to push hard on the screen.

Difference Between Capacitive And Infrared Touch Screen

Of touch screen technologies, infrared and projected capacitive are the top two types that are mostly utilized. However, they are applied to different applications due to the differences between them.

Workings

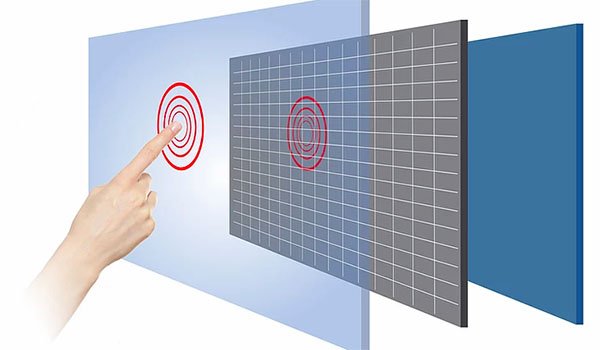

For PCAP touch screens, There is a layer of transparent electrode film that is fixed between the LCD panel and the cover glass, when the human finger touches the screen, the current through that film changes, and the signal of x and y position will be transferred to the computer.

For IR touch screens, the equipment detects the finger’s position by detecting the block of invisible lights from the infrared LEDs that are embedded in the touchscreen frames.

Structure

So you will often see a bezel in the IR touchscreen, which is used to transfer the infrared light to the surface of the overlay, while the PCAP touchscreen does not require the bezels.

Multi-touch

PCAP touch screen only supports two-point input, while IR ones up to 40-point input.

Activated by

IR touchscreen can be activated by anything that is not transparent, whereas PCAP types only accept bare fingers, thin surgical gloves, or cotton gloves.

Price

The electrode film in PCAP touchscreens is expensive, especially when it comes to large screens, but for IR ones, when it is applied to large-scale screens, you only need to add a few LEDs and correspondent detectors, apparently, the IR touchscreen solution is more cost-effective in large interactive displays, such as the interactive digital board, which are used for presentation in business meetings.

Applications

Due to the costs and multi-touch function, the IR touch screen is mostly applied to large screens, however, PCAP is used in smartphones and tablets.

More ideas? Comments, please!